|

INTERNATIONAL ISO

STANDARD 11553-1

Second edition

2020-04

Safety of machinery — Laser

processing machines —

Part 1:

Laser safety requirements

Sécurité des machines — Machines à laser —

Partie 1: Exigences de sécurité laser

Reference number

©

ISO 2020

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: [email protected]

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Hazards generated by laser radiation . 5

4.1 General . 5

4.2 Laser radiation hazards/sources of laser radiation emission . 6

4.3 Laser radiation hazards induced by external effects (interferences) . 7

4.4 Characteristics of laser radiation . 7

5 Safety requirements and measures . 8

5.1 General requirements . 8

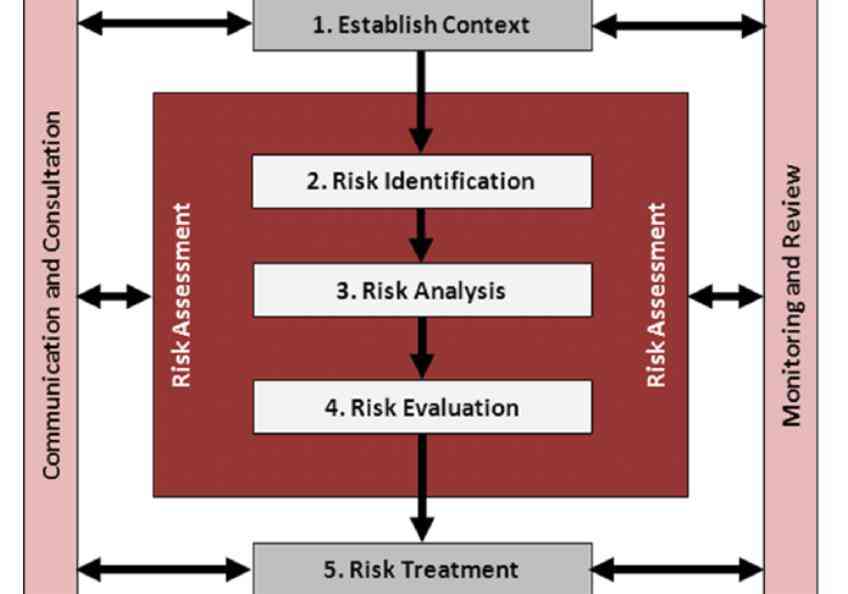

5.2 Risk assessment with regard to laser radiation hazards . 8

5.3 Implementation of risk reduction measures. 9

5.3.1 General. 9

5.3.2 Safety measures against laser radiation hazards in dependence of the locations . 9

5.3.3 Safety measures against laser radiation hazards.10

5.3.4 Engineering control measures .13

6 Verification of the safety requirements and risk reduction measures .14

7 Information for use .15

8 Labelling .16

Annex A (informative) Potential hazards .18

Bibliography .21

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 172, Optics and photonics, Subcommittee

SC 9, Laser and electro-optical systems, in collaboration with IEC/TC 76, Optical radiation safety and laser

equipment.

This second edition cancels and replaces the first edition (ISO 11553-1:2005), which has been technically

revised with the following main changes:

— the terms "beam delivery systems", "beam path components", "beam shaping components", "beam

switching components" and "fibre optic cable" and "fibre connector" were added;

— the document was restructured;

— the Title was adapted;

— other hazards than laser radiation hazards are not considered in this document but are described

in Annex A;

— operating modes (automatic mode, setting mode, manual intervention mode, service mode) and the

operating mode selector switch were added;

— Clause 5 is separated in requirements regarding different locations and the different modes of

operation;

— in Clause 6 the verification procedures were described in more detail;

— Annex B was deleted.

A list of all the parts of ISO 11553 can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

iv © ISO 2020 – All rights reserved

Introduction

The Machinery Safety Directive issued by the European Parliament and the Council of the EC outlines

essential and mandatory requirements that must be met in order to ensure that machinery is safe. In

response, CEN/CENELEC initiated a programme to produce safety standards for machines and their

applications. This document is one in that series.

It has been prepared as a harmonized standard to provide a means of conforming to the essential safety

requirements of the Machinery Directive and associated EFTA Regulations.

This document is a type B standard as stated in ISO 12100. The provisions of this document may be

supplemented or modified by a type C standard.

For machines which are covered by the scope of a type C standard and which have been designed and

built according to the provision of that standard, the provisions of that type C standard take precedence

over the provisions of this type B standard.

The purpose of this document is to prevent injuries to persons by

— listing potential laser radiation hazards generated by machines containing lasers,

— specifying safety measures and verifications necessary for reducing the risk caused by specific

hazardous conditions,

— providing references to pertinent standards, and

— specifying the information which is to be supplied to the users so that they can establish proper

procedures and precautions.

INTERNATIONAL STANDARD ISO 11553-1:2020(E)

Safety of machinery — Laser processing machines —

Part 1:

Laser safety requirements

1 Scope

This document describes laser radiation hazards arising in laser processing machines, as defined in 3.7.

It also specifies the safety requirements relating to laser radiation hazards, as well as the information

to be supplied by the manufacturers of such equipment (in addition to that prescribed by IEC 60825).

Requirements dealing with noise as a hazard from laser processing machines are included in

ISO 11553-3:2013.

This document is applicable to machines using laser radiation to process materials.

It is not applicable to laser products, or equipment containing such products, which are manufactured

solely and expressly for the following applications:

— photolithography;

— stereolithography;

— holography;

— medical applications (per IEC 60601-2-22);

— data storage.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3864 (all parts), Graphical symbols — Safety colours and safety signs

ISO 11145:2018, Optics and photonics — Lasers and laser-related equipment — Vocabulary and symbols

ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk reduction

ISO 13849-1:2015, Safety of machinery — Safety-related parts of control systems — Part 1: General

principles for design

ISO 13849-2:2012, Safety of machinery — Safety-related parts of control systems — Part 2: Validation

ISO 13850:2012, Safety of machinery — Emergency stop function — Principles for design

IEC 60204-1:2016, Safety of machinery — Electrical equipment of machines — Part 1: General requirements

IEC 60825-1:2014, Safety of laser products — Part 1: Equipment classification and requirements

IEC 60825-4:2006, Safety of laser products — Part 4: Laser guards

IEC 62061:2005, Safety of machinery — Functional safety of safety-related electrical, electronic and

programmable electronic control systems

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 11145:2018, ISO 12100:2010,

IEC 60825-1:2014 and IEC 60825-4:2006 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at http:// www .iso .org/ obp.

— IEC Electropedia: available at http:// www .electropedia .org/

3.1

beam delivery system

system comprised of all components, including all optical beam components and potential beam paths

and enclosures, which when combined, transfer laser radiation emitted from the laser (according to

definition in IEC 60825-1:2014) to the workpiece. The beam delivery system can include all elements

for guiding, shaping and switching the laser beams as well as the enclosure of and support for the beam

path components

[SOURCE: IEC 60825-4:2006/AMD 2:2011, G.2.1, modified — replaced "workpiece. These components may

include" by "workpiece and where the components can include" and changed laser beam to laser beams.]

3.2

beam path component

optical component which lies on a defined beam path

Note 1 to entry: See IEC 60825-1:2014, 3.16.

EXAMPLE A beam steering mirror, a focus lens, a fibre optic cable or a fibre optic cable connector.

3.3

beam shaping component

optical component integrated in the beam path to transform the profile or cross-section of the laser

beam by means of apertures, reflective, refractive or diffractive optical components

EXAMPLE Lens or integrating optical element for hardening applications.

3.4

beam switching component

optical component or an assembly of components introduced in the beam path to direct or divert, under

external control, the beam path along (a) predetermined direction(s)

Note 1 to entry: The external control allows the beam path to be switched from one predetermined direction to

another.

3.5

fibre optic cable

optical beam guiding component that enables the transfer of laser radiation along a transparent medium

Note 1 to entry: The fibre optic cable can be equipped with sensors to monitor breakage and/or temperature.

Note 2 to entry: A fibre optic cable can have a glass or another core that carries the laser radiation and

is surrounded by cladding. The outside of the fibre is protected by cladding and can

...