"Xinhai", "Jindi", "Tianyang".

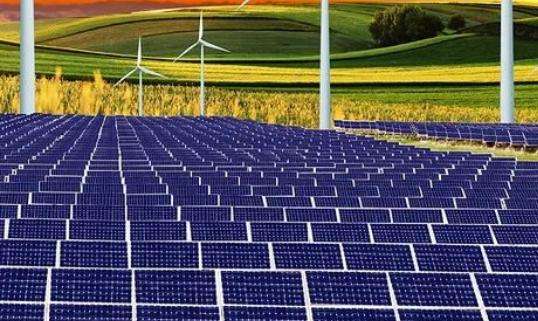

Generally speaking, 1 square meter of crystalline silicon solar panel is equivalent to about 120-140 W. If calculated as 120 W, the sun at 6 hours a day is 120*6 = 720 WH.

Types of solar panels:

Monocrystalline silicon solar cells:

Currently monocrystalline Conversion photoelectric The efficiency of silicon solar cells is about 15%, the highest reaching 24%. This is currently the highest photoelectric conversion efficiency among all types of solar cells. However, the production cost is so high that it cannot be widely and commonly used. use in large quantities.

How much does a square meter of photovoltaic solar panels cost?

Which is better, monocrystalline solar panels or polycrystalline solar panels?

< p>Solar panelss monocrystalline panels are slightly better than polycrystalline solar panels in terms of conversion efficiency, power output and stability.However, the cost of polycrystalline solar panels is lower and is suitable for large-scale power generation projects.

Overall, monocrystalline solar panels are more suitable for scenarios with higher performance requirements, while polycrystalline solar panels are more suitable for scenarios where economy is a priority.

Which is better, monocrystalline silicon or polycrystalline silicon solar panels?

According to the December 2019 price, the price of 'a square meter of photovoltaic solar panels costs 600 yuan.

Billing is based on power. A normal map measures 1.65 * 0.998 = 1.6467 square meters. The current market price of all products isabout 8 yuan/W. The power of each component of current domestic products is 270W. You can calculate the price of each component. i.e. 270*8 = 2160 yuan. These are terminal retail prices.

Photovoltaic prices are calculated in watts and not in surface area. Generally speaking: the installation area of 3KW system is about 22㎡, 4KW system is about 30㎡, 5KW system is about 40㎡, and 6KW system is about 50㎡. About 1kw10 square meters.

Detailed information:

The European Trade Commission could propose in May to impose punitive customs duties of more than 30% on Chinese solar panels to to protect European manufacturers.

Reuters cited diplomats as saying that EU Trade Commissioner Karel De Gut would propose imposing tariffss punitive customs duties on Chinese solar panels at the meeting of EU trade representatives on the 8th, and that it should receive support. In accordance with current European regulations, the relevant temporary tax measures will come into force before June 6.

However, although the EUA preliminary decision will be made at that time, leaving room for negotiation with China to resolve the issue. If both parties successfully negotiate, they can avoid punitive tariff measures that can be implemented for up to five years.

The European Commission has launched anti-dumping and countervailing investigations respectively into solar panels imported from China, involving Chinese companies' exports to the EU worth up to €21 billion (approximately 27.6 billion US dollars), which is called by industry insiders the largestnth “double counterfeiting” case involving the largest sum of money in the history of the European Union.

I think polycrystalline silicon and monocrystalline silicon solar panels are better than polycrystalline silicon.

1. Low cost

The speed of polycrystalline silicon solar panels is generally two to three times that of monocrystalline silicon, and the voltage is more stable. The manufacturing process of polycrystalline silicon solar cells is similar to that of monocrystalline silicon solar cells. Its photoelectric conversion efficiency is about 12%, which is slightly lower than that of monocrystalline silicon solar cells. However, the material is easy to manufacture, saves energy. and the overall production cost is low, so there is a lot of development.

2. Beautiful craftsmanship

The single crystals are arranged inorderly manner, while polycrystalline crystals are arranged in a disorderly manner. This is mainly determined by their processing technology. produced by casting methods, which means directly pouring silicon into a crucible to melt and shape it, while single crystal adopts Siemens method to improve Czochralski. The Czochralski process is a process of reorganization of the atomic structure. To our naked eyes, the surface of monocrystalline silicon looks the same, while the surface of polycrystalline silicon appears to contain a lot of broken glass, making it sparkle.