EVA is a copolymer of ethylene and vinyl acetate. It is the fourth largest polymer in the ethylene series after HDPE, LDPE and LLDPE. It is a typical statistical copolymer. In its molecular structure, the substituents are arranged irregularly on the molecular chain. At the same time, the asymmetric carbon atoms in the molecular chain have different configurations and irregular arrangements. It is therefore a less crystalline and polar material. flexibility. In addition, it has good wettability when heated and melted, and has good flexibility, stress crack resistance and bonding performance when cooled and solidified.

The properties of EVA mainly depend on its vinyl acetate (VA) content and its melt flow index (MI). When the VA content increases and MI remains unchanged, the transparency increases and the adhesion strength also increases, and theCorresponding properties such as crystallinity, hardness, softening point, stiffness, tensile strength, chemical resistance and resistance to thermal deformation are all the same. Decrease ; when the MI increases and the VA content remains unchanged, that is, the molecular weight of EVA decreases and the melt viscosity, toughness, tensile strength and strength to cracking under corresponding environmental stress all decrease. EVA used for solar cell packaging requires light transmission above 90% and good weather resistance. Currently, EVA materials with VA content of 26-33% are widely used.

Pure EVA itself is a linear polymer, a thermoplastic resin, and does not cross-link to form a three-dimensional network structure. Usually when applying it as adhesive film of inkapsulation, a certain amount of cross-linking agent and co-cross-linking agent must be added to cross-link the molecular chains with each other, thus making them thermoset. The cross-linking and curing process during the encapsulation process is the decomposition of peroxide cross-linker (RO-OM) into free radicals RO· and MO·, which triggers the combination of EVA molecular branched vinyl acetate (VA) to form a three-dimensional network structure, cross-linking and curing of EVA

Advantages, disadvantages and modifications of EVA encapsulation materials

Solar cell modules generally need be used normally for 25 hours. 30 years, and because solar cell modules usually work outdoors, so the environment is relatively harsh, so the requirements for packaging materials are more strict. EVA has the characteristics of ttransparency, softness, hot melt adhesiveness, low melting temperature and good melting fluidity. These characteristics meet the requirements of solar cell packaging materials. However, pure EVA has poor heat and humidity resistance and UV resistance, is prone to aging and yellowing, has poor cohesive strength and poor creep resistance. This will affect the photoelectric conversion efficiency and lifespan of solar cells. to modify EVA to improve molecular structure and weather resistance. The main reason for the aging and yellowing of EVA film is that its molecular chain has a linear structure, composed of carbon-oxygen bonds, carbon-hydrogen bonds, etc. These chemical bonds will break, recombine, or oxidize in humid, outdoor conditions. alternating hot environments and irradiation with ultraviolet lightHead, this produces chromophores, causing the EVA film to yellow and degrade. Current methods of modifying EVA mainly focus on adding cross-linking agents to cross-link it and adding some additives with functions such as antioxidant, UV absorption or stability to the light. The cross-linking agents are generally organic peroxides. During the heating and encapsulation process of solar cells, the adhesive film A will be thermally decomposed to generate free radicals, which will trigger the EVA molecular chains to combine to form a structure of network and increase molecular stability. Added additives such as antioxidants, UV absorption or light stability can generally reduce the oxidative decomposition rate of EVA film, improve anti-aging and UV performance, and reduce the degree of yellowing. crosslinks in the EVA sealant will also react chemically with these additives upon prolonged aging, causing bubbles and yellowing of the adhesive film during use.

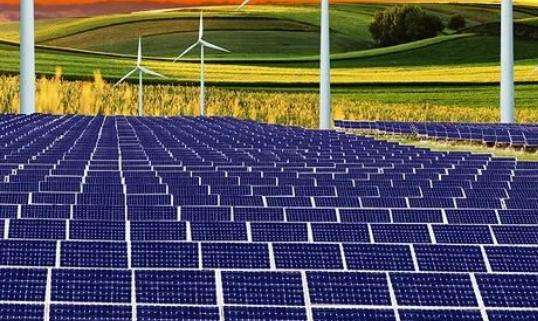

EVA is a hot melt adhesive film mainly used in the production of photovoltaic modules. Ordinary photovoltaic modules are placed with tempered glass, EVA, cells, EVA and TPT up and down in the laminator, through suction, heating, pressurization and fusion of EVA, the layers are tightly bonded together to achieve the insulation function. drum sheet from the air.