|

Ref. No.: IS0 / R 149 - 1960 (E)

IS0

I N T ER N AT I O N A L ORGAN IZAT 1 ON FOR S TA N DARD 1 Z AT I O N

ISO R$OMMENDATION

MODIFIED ERICH CUPPING TEST

FOR STEEL,^^

1st ED IT10 N

February 1960

COPYRIGHT RESERVED

The copyright of IS0 Recommendations and IS0 Standards

belongs to IS0 Member Bodies. Reproduction of these

documents, in any country, may be authorized therefore only

by the national standards organization of that country, being

a member of ISO.

For each individual country the only valid standard is the national standard of that country.

Printed in Switzerland

Also issued in French and Russian. Copies to be obtained through the national standards organizations.

---------------------- Page: 1 ----------------------

BRIEF HISTORY

The IS0 Recommendation R 149, Modijîed Erichsen Cupping Test for Steel Sheet and

Strip, was drawn up by Technical Committee ISO/TC 17, Steel, the Secretariat of which

is held by the British Standards Institution (B.S.I.).

Cupping tests were first considered during a meeting of Working Group ISO/TC

17/WG 1, Methods of mechanical testing for steel, held in London in November 1954. This

discussion led to a proposal covering both the Erichsen and the Olsen cupping tests, which

the Working Group submitted to the Technical Committee during its fourth plenary

meeting, held in Stockholm in June 1955. The Technical Committee decided to refer the

question back to the Working Group for study, requesting it to continue its efforts with

a view to setting up a proposal dealing with a single cupping test.

During the fifth plenary meeting of ISO/TC 17, held in London in March 1957, the

Working Group submitted a draft proposal for a single cupping test, and this was adopted,

subject to a few minor amendments. Following the decisions reached at that meeting, the

Secretariat drew up a new draft proposal, which was submitted to all the Members of the

Technical Committee for vote by letter ballot. This new draft proposal was accepted,

subject to a few amendments, and in its revised form was adopted as a Draft IS0 Recom-

mendation.

On 11 July 1958, the Draft IS0 Recommendation (No. 209) was distributed to all the

IS0 Member Bodies and was approved, subject to small editorial modifications, by the

following 24 Member Bodies :

Australia Finland New Zealand

Austria France Norway

Belgium Germany Poland

Bulgaria Hungary Romania

Burma India Spain

Chile

Israel Sweden

Czechoslovakia

Italy Switzerland

Denmark Japan Yugoslavia

Two Member Bodies opposed the approval of the Draft:

United Kingdom U.S.S.R.

The Draft IS0 Recommendation was then submitted by correspondence to the IS0

Council, which decided, in February 1960, to accept it as an IS0 RECOMMENDATION.

-3-

---------------------- Page: 2 ----------------------

IS0 / R 149 - 1960 (E)

IS0 Recommendation R 149 February 1960

MODIFIED ERICHSEN CUPPING TEST

FOR STEEL SHEET AND STRIP

1. PRINCIPLE

The test consists in :

pressing the clamped test piece into a die by means of a ball or a tool (penetrator) with a

spherical end until rupture commences;

measuring the depth of the cup.

2. SCOPE

The test as defined below is normally applicable to products having a thickness of not less than

0.5 mm and not more than 2 mm. It may however be extended to products having a thickness

less than 0.5 mm by agreement between the parties concerned.

3. SYMBOLS AND DESIGNATIONS

~

Number Symbol Designation

1 a Thickness of test piece

2 Side, width or diameter of test piece

Bore diameter of die

3

Bore diameter of retaining ring

4

5 External diameter of die

6 External diameter of retaining ring

7 Corner radius of interior of die

8 Corner radius of exterior of die

9 Corner radius of exterior of retaining ring

10 Depth of bore of die

11 Thickness of die

12 Thickness of retaining ring

13 d Diameter of spherical end of penetrator

14 Depth of cup

-

IE Cupping number

-4-

---------------------- Page: 3 ----------------------

IS0 / R 149 - 1960 (E)

90 min.

a

0 55 f 0.7

i-01

I mI I9

0 55 f 0.1

e

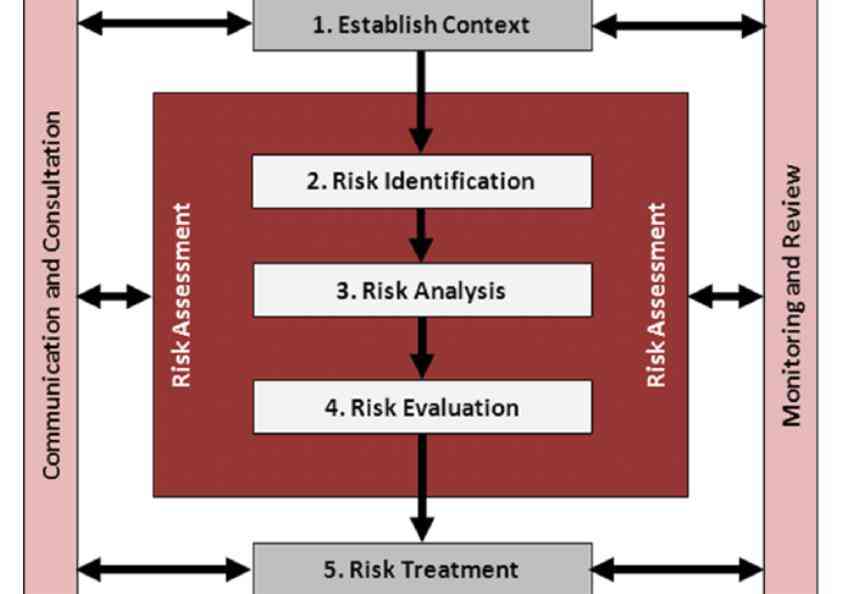

FIGuRE.-Cupping test.

4. TESTING MACHINE

The die, the retaining ring and the penetrator should be sufficiently rigid not to deform

4.1

appreciably during the test.

4.1 .I The penetrator should not turn during the test.

4. I. 2 The construction of the machine should be such that it is possible to determine accurately

the moment when rupture commences.

4.1.3 The surfaces of the retaining ring and of the die in contact with the test piece should

be plane, polished and parallel to each other and pe

...